How to Facet Gems

A Detailed information and guide on How to Facet Gems. In faceting, HAI is much more than a casual idiom. HAI meaning, H - Height, A- Angle and I- index.

6 Minute Read

The Faceting of a Gemstone Only Appears Complete and Critical

Don't be Fooled: Artistic Talents and Mechanical Skills Aren't the Critical Factors to Success, Patience Is

To the average person, viewing a magnificently faceted diamond or colored gemstone, the complexity appears awesome. How do you manage to cut all those bright, tiny facets? It must take enormous talent. They are queries often heard by faceters.

Usually a faceter will nod smugly and make light of his or her apparent genius, a mode too often dedicated to keeping you awed. If the question is posed to an honest gemcutter, s/he might respond with a famous Japanese idiom, "HAI." HAI is a marvelous all-purpose expression that means, "yeh, yeh . . . I suppose so . . . OK . . . I'm cool . . . I get it . . . I'm with you . . .go ahead . . . etc."

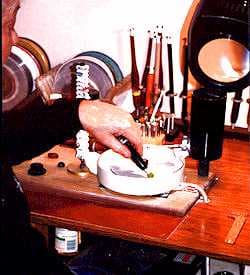

Faceting methodology consists of mounting a gem crystal on a metal dowel, (dopstick), which fits into a quill, then rigidly addressing the Height-Angle-Index triangle with the faceting machine, and touching the locked-in-place crystal to abrasive laps in two sequential operations, faceting first the top (called the "crown") and then the bottom (called the "pavilion").

In faceting, HAI is much more than a casual idiom. It is an absolute ruling principle, expressed as an acronym with it's significance focused on "go ahead." When a faceter can say HAI to his or her faceting progress, it means "OK to go ahead" (and facet) because the vital triangle is in place (as shown in "B" above) with the gemcutter incontrol of the three principle elements of faceting:

H — height

A-angle

I-index.

Height controls the depth to which a facet is cut and this enables a faceter to establish even, uniform rows of same sized, same depth facets. Angle establishes the plane upon which each facet is cut because optics and performance is so dependant on each facet(s)possessing just the right amount of plane or slant. Index refers to the placement of the facets around the shape or outline i.e., a round brilliant cut stone, like most diamonds, shows eight main facets when viewed straight down in "plan view."

These three important elements are more fully explained below.

Four Simple Steps . . .

For the most part, you can take all the mysticism and incantation, secrecy and ritual and downright nonsense, roll it up into a ball and toss same in a faceting scrap heap. Faceting consists of four simple elements:

1) a person to set and hold the machine

2) the faceting machine

3) abrasive disks to do the cutting and polishing

4) a piece of natural or man-made crystal to cut

It may look complex, but one must merely glue or attach a stone to a metal dowel (called a dopstick, then set the machine's mast (for H), adjust the protractor or quill position (for A), place the trigger grip in the numbered notch in an index wheel (for I). Next, s/he lowers the stone to the abrasive lapwheel and monitors cuttingand polishing progress. There really isn't much more to it than that which is why faceting can actually be learned in a few hours. That learning process will allow one to cut the most famous and easiest cut of all, the famed American round brilliant whose shape and appearance symbolizes and dominates the entire fieldof gemcutting. Truth is, nine out of 10 gemstones are cut in the round brilliant mode or one of its variations. How is this possible? The answer is simple. Modern faceting machines are actually milling machines (it's not by chance that the leading faceting machine manufacturers are machinists by trade).

All three HAI controls (mast, quill, index wheel)are routinely locked in during setup before a faceter even starts to cut. As a result, the faceter needs only "patience," the ability and mind set to hold the locked-in-place stone against an abrasive wheel and watch the progress. Amongfaceters " . . . cut and look . . . cut and look . . . " is a time honored reality.

The Four P's of Gemstone Analysis . . .

If you never cut a gemstone but want to be able to evaluate one professionally, keep in mind that any cut-diamond or colored stone-is evaluated on the basis of what I callthe 5 P's of cut appraisal:

1)-Points (edges and intersections meet precisely which provesthat facets have been cut evenly and uniformly)

2)-Proportions (for the height of most faceted gems the top part represents 1/3 and the bottom part represents 2/3

3-Polish (a fine polish proves that the previous steps, too, were done properly)

4)-Positioning (an astute faceter has studied the gem crystal andoriented to conform with optical laws and to minimize the visibility and interference of imperfections and, finally,

5-Performance (if the vital angles are observed, the stone's facets reflect and refract the maximum amount of external and internal light i.e., it will perform optically - even when tilted or tipped away from normal. This reflective capability contrast with an uninteresting piece of see-through glass when the gem is viewed straight down through the table).

All of a faceter's efforts are focused through HAI to accomplish these Five P's mentioned above. Here's how it's done.

Faceting Fundamentals . . .

Faceting methodology consists of (A) cutting appropriate angles on the top and bottom of a gem crystal, because (B) the faceting machine forms a right triangle that controls the stone's angle on the abrasive disk, and (3) a faceter to hold the stone against the turning lap wheel and monitor progress in cutting the "crown" i.e, the top of the gem, and the "pavilion" i.e., the bottom of the gem. Obviously, traditional faceting is a two-step process...

H = Height As explained above, very faceting machine must form a right triangle so the target angle will appear at the stone-abrasive disk intersection. To accomplish this, the faceting head is raised on its mast (in a protractor machine) or the quill's tailpiece in a jamb peg machine is placed in an elevated slot on the back- board jamb. In both cases the quill's are locked at an elevation consistent with the stone's diameter or width. This action coordinates the machine's quill to the stone so height is no longer an issue.

A-Angle. Once the quill's elevation is established, angle setting becomes a cinch. The mechanical protractor stop is set to the targeted angle or the jamb peg's quill tailpiece is slipped into the appropriately numbered angle slot. This effectively assures that the cut facet will finish up at the desired angle. Thus, setting angles involves merely a simple dial-up task or a put-it-in-the-right-slot proposition. Your greatest danger consists in setting the angle position wrong.

I-Index. Placing all those "tiny" facets around and about a faceted gem demands little more than slipping a trigger into a numbered gear notch. If the instructions tell you to put the trigger in the "2" notch to cut a particular facet, that's what you do and the task is done . . . the faceting machine will dutifully cut a nice particular facet at the right angle and at the place you want. Again, your greatest danger consists in placing the trigger in the wrong notch.

That's it! Observe HAI on every facet and you'll achieve the 4 P's every time you cut a stone. As for the supplementary heady stuff concerning proper angles, conversion of notch numbers from one index gear to the next, reflectivity, etc., well, that's a cinch, too. If you're not a mathematician or if you don't want to memorize a lot of formulas, refer to the FacMath utilities in the Reference Section and your PC computer will make you a wizard in a minute or so - and you won't make any arithmetical mistakes either.

This article is part of a series as follows:

Dr. Gerald Wykoff GG CSM

Dr. Gerald Wykoff is GG (Graduate Gemologist), a CSM (Certified Supreme Master gemcutter), educator, and author of several gemology books. He founded the American Society of Gemcutters in the 1980s and served for more than 10 years as the editor of its monthly magazine, American Gemcutter.

Related Articles

The White Paper Test and Rough Gem Buying

Faceting Made Easy, Part 1: Gemstone Properties

Getting Started on Dopping with Wax

Opal and Pearl Care Guide

Never Stop Learning

When you join the IGS community, you get trusted diamond & gemstone information when you need it.

Get Gemology Insights

Get started with the International Gem Society’s free guide to gemstone identification. Join our weekly newsletter & get a free copy of the Gem ID Checklist!